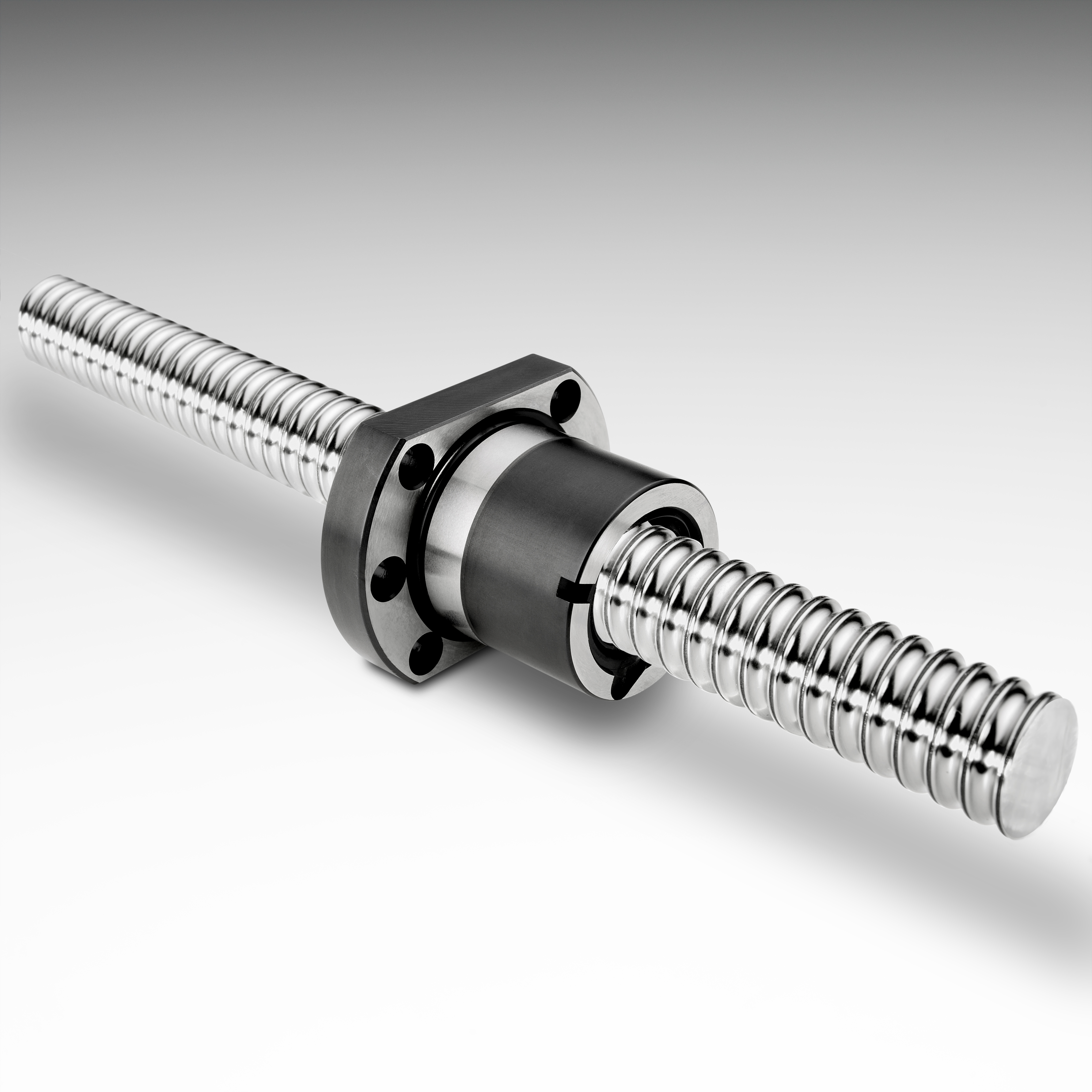

Thomson high-load ball screws provide maximum load capacity and longer life in a compact envelope!

THOMSON BALL NUT FULL

We know you don’t have hours to spend researching and navigating part numbers to find the right ball screw for your design project. Thomson’s enhanced online product finder tool for ball screws simplifies the search and selection process, helping you quickly identify the right part, access pricing and lead times, and immediately purchase your final selections – all in one place.Contact ISC Companies for Thomson Industries High-Load Ball ScrewsĪs an authorized distributor of Thomson Industries and Altra Industrial Motion-who acquired Thomson in 2018-ISC Companies can supply the full line of Thomson linear motion products, including their high-load ball screw that was introduced in 2019. They are skilled at evaluating your requirements and designing assemblies that fit your needs.įind your ideal ball screw solution in only a matter of minutes

Thomson field sales and applications engineering personnel have more ball screw expertise than any other group in the industry. Application Support. Working with Thomson is like having your own staff of ball screw design engineers able to address application concerns and recommend solutions.Expert manufacturing using the most modern equipment available provides ball screws that set the standards for performance, precision, and travel life. In-house manufacturing capabilities include our proprietary heat treating and plating processes. Manufacturing. Thomson maintains the most modern and complete ball screw manufacturing facilities in the industry.They can also select and recommend materials best suited to your particular application. Our in-house metallurgists control and verify that the materials used are of the highest quality.

Materials. The materials used to manufacture ball screws are critical to their performance.Your ball screw is inspected every step of the way to ensure top quality and performance. Quality. With a vast background in flight-critical aerospace and defense applications, Thomson is uniquely positioned to provide the highest levels of quality across our full line of ball screws. Our fully equipped engineering laboratory performs qualification testing for mechanical performance, environmental effects and structural integrity.Available in a full range of diameters, leads and ball nut configurations, in either pre-loaded or non-pre-loaded types, and all in industry standard envelopes, our ball screws provide dependable accuracy and repeatability at an economical price. Design. Through extensive research and evaluations, Thomson engineers have been able to develop a comprehensive ball screw offering that delivers optimal solutions for countless applications.Precision ball screws are not all alike. Whether it be metric ball screws, inch ball screws or miniature ball screws, key differences affect their performance and extend their lives.

0 kommentar(er)

0 kommentar(er)